Knowing how to choose a hollow metal door frame and door assembly is one of the most critical decisions for any commercial or industrial project. When durability, security, and fire safety are non-negotiable, a steel door is the clear choice. But with terms like ‘steel gauge,’ ‘knock-down frames,’ and ‘core types,’ selecting the right components can be a challenge.

This simple 5-step guide will walk you through everything you need to know to make the perfect choice for your facility.

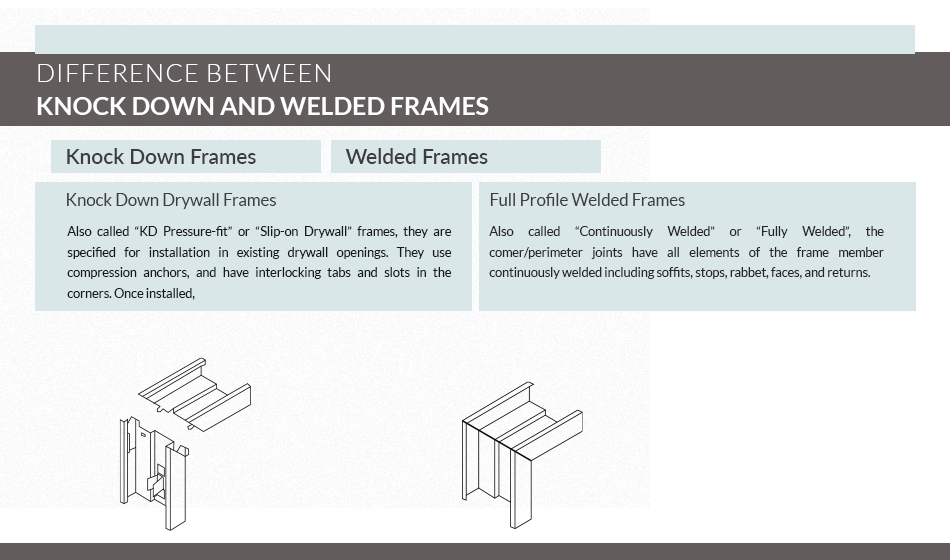

The first step in how to choose a hollow metal door frame is deciding on the frame’s construction. This choice depends entirely on your wall type and when the frame will be installed.

Welded Frames: These arrive as a single, fully welded unit. They offer maximum strength and are the required choice for most new masonry (block) construction and high-security areas.

Knock-Down (KD) Frames: These arrive in three pieces (a header and two jambs) and are assembled in the opening. KD frames are the perfect solution for retrofitting into existing drywall or stud walls, offering much greater installation flexibility.

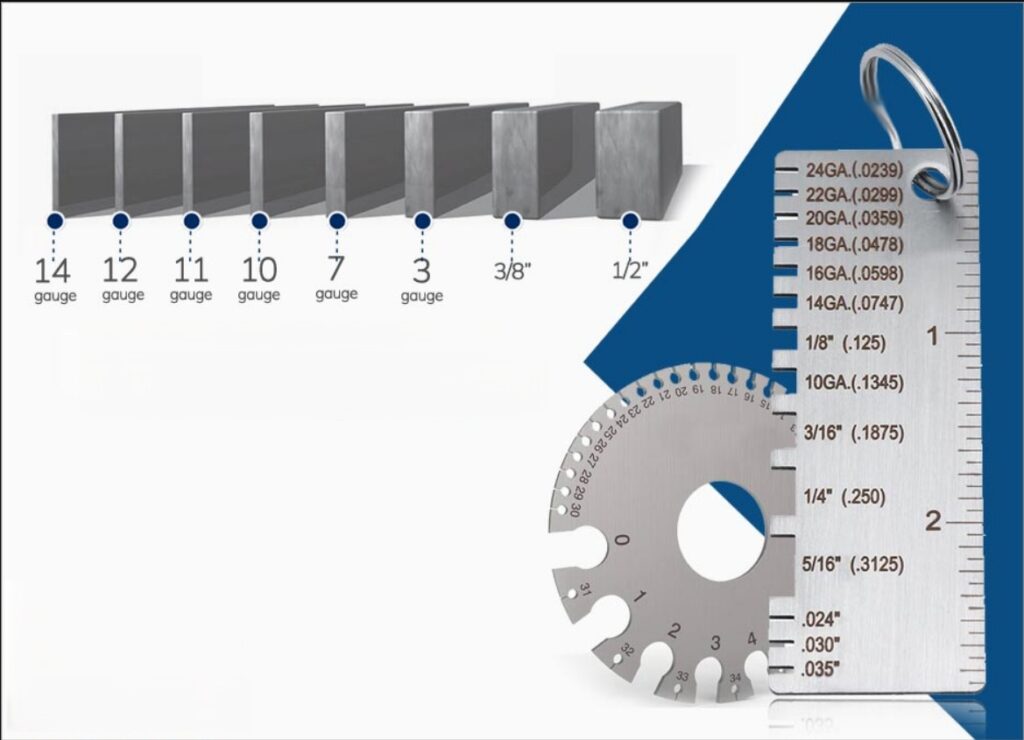

Gauge refers to the thickness of the steel; the lower the number, the thicker and stronger the steel.

18 Gauge (Standard-Duty): Perfect for most interior office doors and light commercial use.

16 Gauge (Heavy-Duty): This is the most common and versatile choice. It’s ideal for high-traffic entrances, schools, and hospitals.

14 Gauge (Extra Heavy-Duty): Reserved for high-security applications or locations prone to vandalism and extreme abuse.

What’s inside the door matters. The core provides insulation, sound control, and structural integrity.

Honeycomb (Standard): A lightweight cardboard mesh, standard for most interior applications where sound and temperature control are not priorities.

Polystyrene (Insulated): A foam core that provides increased thermal insulation (R-value), ideal for exterior doors to improve energy efficiency.

Steel Stiffened (Maximum Security): A steel grid inside the door for maximum strength, impact resistance, and security.

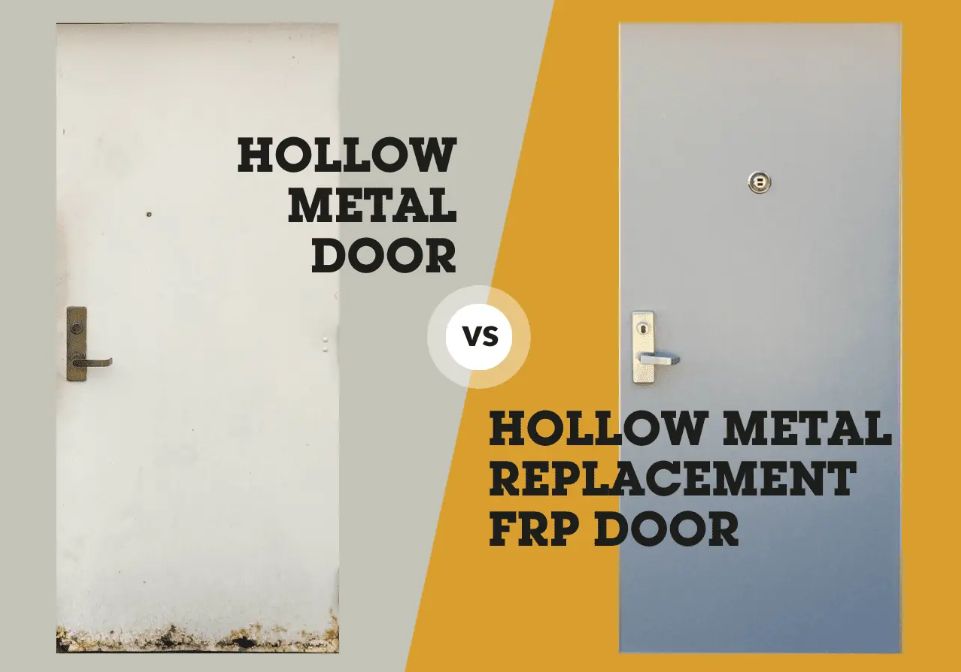

For environments facing moisture or chemicals, FRP (Fiberglass Reinforced Polymer) doors are a key alternative. While a hollow metal door will rust if its finish is compromised, an FRP door is completely waterproof and highly resistant to chemicals, making it the superior choice for pools, food processing plants, and coastal areas.

One of the primary functions of a hollow metal door frame assembly is fire protection. These systems can be rated for up to 3 hours, creating a critical barrier to stop the spread of smoke and fire. Ensuring your assembly has the correct fire rating is essential for passing building inspections. For more details on compliance, you can refer to the standards set by the Hollow Metal Manufacturers Association (HMMA).

Knowing how to choose a hollow metal door frame also means planning for your hardware. Ensure the frame and door are properly reinforced and prepped for the specific hinges, locks, and closers you plan to use. Incorrect hardware prep can lead to costly on-site modifications and delays.

At Prime-Door, we don’t just supply hollow metal doors and frames; we fabricate them. Our in-house welding and modification shop in Youngstown gives us the unique ability to create custom frames and prep your doors with precision hardware, ensuring a perfect fit and a faster installation for your project.

Now that you know how to choose the right components, the next step is to explore your options. Our main hollow metal door frame service page has the product details and information you need to move forward.

Contact us for a custom, project-specific quote. Configure your perfect door hardware and get a quote today.